HPM115 S15 HYDRAULIC PROGRAM-CONTROL PAPER CUTTING MACHINE

HPM115 S15 HYDRAULIC PROGRAM-CONTROL PAPER CUTTING MACHINE

32,500 $

Product Description

HPM115 S15 HYDRAULIC PROGRAM-CONTROL PAPER CUTTING MACHINE

1.Full touch display screen made by Japan-based SHARP

2.German operating system is equipped to meet the operating habits of domestic users and guarantee convenient operation.

3.Mainboard adopted industrial chip imported from Italy.

4.Highly sensitive of the touch screen has real-time responses.

5.Equipped with signal amplification function and exvellent anti-interference to avoid dimension errors due to drive aging.

6.Dimesnsion in front of knife will bedisplayed to facilitate sizes for cutting.

7.Program storage capacity is 200 programs each program can store 200 items cutting size

8.Computing with four operations output programs in real time

9.Position resolution of backgauge is 0.01mm, closed-loop control the locating error is less 0.01mm No need to adjust locating error. Max backgauge speed 20m/min for S15 30m/min for S19 38m/min for S22.

10.Equipment has relative positioning function relative to current position.

11.With minimal compensation it can rapidly correct program errors due to paper distortions.

12.It can rapidly find out user-defined number of cutters

13.Each air cushion program can be programmed.

14.The time of automatic cutting signals can be set up and cancelled single automatic cutting can be started by inputting a password.

15.High and low speeds can be manually switched over rapidly.

16.A paper pushing program is equipped t opush paper automatically so as to guarantee safety and enhance operation efficiency.

17.Automatic cutting can be made as per instructed programming.

18.Display precisions is 0.01mm.

- Multiple languages such as chinese and english are available for order management.

20.Manual and automatic operations can be rapidly switched over to enhance efficiency to the greatest extent.

21.Voice messages are equipped to make users judge equipment condistions correctly.

Main feature:

- Increase efficiency by 35%

- Traditional combined industrial printing for 10 hours

- Intelligent combined industrial printing task only 6.5 hours

- CIP4 imposition cutting system

- It can parse files in JDF format and other various irregular imposition files.

- Operation interface is simple and clear visual cutting program and snimation guidace could be created automatically It will make sure there is no error taken place in cutting process.

- Wifi and wire line networks are both available it can read and parse files directly from imposition computer A network socket is resrved for data transmission.

- The cutting file created by imposition is compatible with various intelligent device

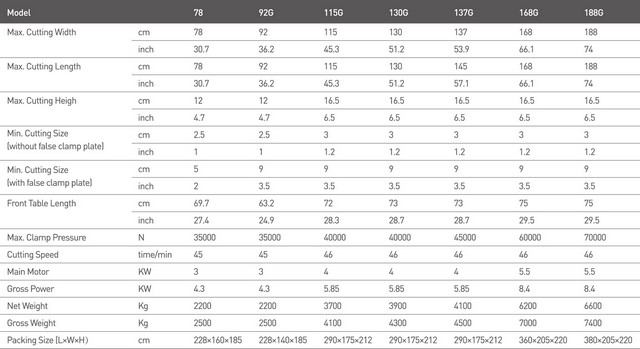

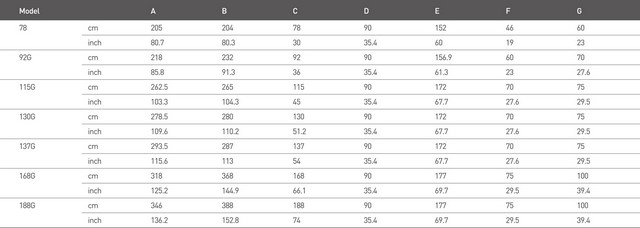

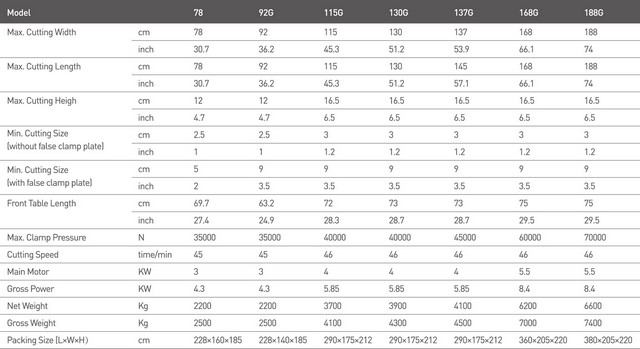

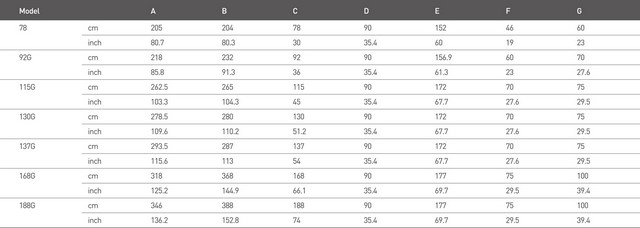

Technical parameter:

| Kod | (NİN) |

|---|---|

| Yıl |